WHAT IS POLYURETHANE FOAM?

Flexible polyurethane foam helps in providing comfort to everyone, every day.

It is best known for supporting our body for a large part of the day, in mattresses, upholstered furniture and car seats. What is sometimes less known is that we enjoy the benefits of hundreds of polyurethane foam articles without even noticing. Its applications are virtually endless, ranging from small but essential items such as sponges in the kitchen, medical dressings to large filters and soundproofing systems that keep our environment clean and quiet.

Polyurethane is a leading member of the wide-ranging and highly diverse family of polymers or plastics. Polyurethane can be a solid or can have an open cellular structure, in which case it is called foam… and foams can be flexible or rigid.

As simple explanation, manufacturers make polyurethane foam by reacting polyols and diisocyanates, both products derived from crude oil. A series of additives are necessary to produce high-quality PU foam products, depending on the application the foam will be used for.

Each form of polyurethane foam has many uses:

EUROPUR represents the producers of flexible polyurethane foam blocks used in the applications presented on this website (bedding, furniture, automotive and many others).

Some flexible PU foams are also moulded, especially for use in the automotive sector, mainly for car seats. For more information on moulded foam applications, please visit the website of EURO-MOULDERS, the European Association of Manufacturers of Moulded Polyurethane Parts for the Automotive Industry.

Rigid foams are mainly used for thermal insulation of buildings and are in the remit of our partner organisation, PU Europe, which has developed a website specifically dedicated to answer all questions on building insulation with polyurethane foam.

For more extensive information on all applications of polyurethanes, please visit the website of ISOPA, the European Diisocyanate and Polyols Producers Association, and polyurethanes.org

APPLICATIONS

Without us even noticing, many of the products that can be found in our homes and offices are (at least partly) made out of polyurethane foam. Foam is present in various comfort products, such as in mattresses and pillows we sleep on or in the upholstery of our sofas or (office) chairs. Due to its insulation, shock absorption and comfort properties, it is widely used for flooring underlay.

Out of total produced flexible polyurethane foam in Europe, around 75% is used in bedding and upholstery.

The mattress is the single most important element of every bedroom. People on average spend a third of their life on it and it is common knowledge that getting good rest is an important factor of an active and happy life. Buying a mattress is therefore essential when it comes to one’s health and well-being.

Depending on the material constituting the core, mattresses are generally classified in four categories: polyurethane foam, latex, springs and hybrid. Most mattresses do however contain layers of polyurethane foam in varying proportions, thanks to its unique properties for comfort and support. Mattresses produced in Europe contain between 2 and up to 30 kg of polyurethane foam.

Almost 50 million mattresses are produced in the European Union per annum. Of those, the market share of mattresses with a polyurethane foam core is estimated to be around 42%. This share is steadily growing, due to the outstanding properties of such mattresses.

But mattresses are not the only bedding product made with polyurethane foam. It is also used in pillows and cushions.

Different polyurethane foam qualities can be used in the same mattress or pillow in order to create products with the properties requested by customers: high resilience foam, memory foam, antibacterial foam, breathable foam… The combinations are virtually endless.

Selecting the right bedding products can sometimes be rather confusing. Much depends of course on personal preference. However, there are also product safety labels existing to help consumers make an informed choice.

One of them is CertiPUR, which attests that the polyurethane foam contained in the product conforms to EUROPUR’s stringent environment, health and safety standards for PU foam. The specifications of CertiPUR have been taken over in the EU Ecolabel criteria for mattresses, which is a label well-known to consumers. Other well-known private quality labels such as the Blue Angel or Oeko Tex 100 are also found on bedding products to allow consumers to make their choice with confidence.

People today have more comfortable, more creative, more varied, complex, durable and more affordable furniture than ever before. In large part, this is thanks to polyurethane foams.

Sofas, armchairs and all sorts of seating rely on foams as filling materials. The great advantages of polyurethane foams are their ability to respond to specific requirements for each application (e.g. density, elasticity and durability) and at prices which make the end products well in reach of the average household. It is estimated that 90% of upholstered furniture has a polyurethane foam filling.

Carpet underlay is the cushioning that makes carpet feel soft and luxurious and increases its lifetime. It is widely used in Anglo-Saxon countries. It is produced mainly from recycled trim from production waste.

Underlay improves floor insulation to keep the room at a reasonable temperature, reducing heating and cooling costs. Given it’s luxurious cushioning and comfort underfoot, PU foam carpet underlay has fast become the most popular type of underlay, widely used in Anglo-Saxon countries. It’s light, easy to handle and made from 85% recycled materials, so it’s kind to the environment too. It’s great for keeping in the heat, reducing sound levels and available in different types of thickness, density and quality.

Does your car have anything in common with a space shuttle? As a matter of fact, yes, they both heavily rely on polyurethane foam. As do planes, boats and trains.

The main applications of polyurethane foam in transport applications are for trimming, seats, headrests, (air-conditioning) filters and acoustic insulation. Depending on the application they are being used for, these foams have to comply with specific performance and emission standards.

Polyurethane foam is an essential material for a modern car. There is approximately 25kg of PU foam in every automobile, with more than half used for automotive seating. By reducing weight of the car, PU foam helps saving energy and increasing its overall longevity.

Almost all car seats in Europe are made of flexible moulded polyurethane foam. Moulded polyurethane foam parts in the automotive industry is in the remit of our sister organisation, EURO-MOULDERS. Some other applications where polyurethane foam parts are used include head-rests, armrests & consoles, bumpers, carpet underlay, headliners, dashboard, instrument insulators, door panels, steering wheels, amongst others.

Polyurethane foam is an essential material for a modern car. There is approximately 25kg of PU foam in every automobile, with more than half used for automotive seating. By reducing weight of the car, PU foam helps saving energy and increasing its overall longevity.

Almost all car seats in Europe are made of flexible moulded polyurethane foam. Moulded polyurethane foam parts in the automotive industry is in the remit of our sister organisation, EURO-MOULDERS. Some other applications where polyurethane foam parts are used include head-rests, armrests & consoles, bumpers, carpet underlay, headliners, dashboard, instrument insulators, door panels, steering wheels, amongst others.

Because of the variety of foams, their lightweight and atmospheric adaptability, polyurethane foams are widely used in aviation industry. They can be found most commonly in spacecraft and aircraft seating. Apart from this, PU foam is also used in insulation of the aircraft, its ceilings and walls, baggage sections, and separators between lavatories and class segments. A small quantities of flexible PU foam significantly improve safety and performance of fuel tanks.

Combustion modified polyurethane foams are the main material used for railway seating in Europe, but also globally.

Polyurethane foam can acquire very different characteristics in relation to density, softness, tensile strength, ball rebound, compression load deflection, etc. Because of its unique properties, polyurethane foam can be used in a variety of everyday products, like the ones below.

One would think that there is nothing as simple as a sponge. Not quite. Polyurethane foam sponges can be made in several varieties depending on what they will be used for. For example, fine pore hydrophilic sponges have a great level of absorbency and work best on smooth surfaces. Open, rugged style cleaning sponges are better for cracked surfaces. Some are anti-bacterial, others are abrasive. And of course, there are a multitude of shapes and colours available on the market.

One product we are using on a daily basis are kitchen sponges, made out of flexible polyurethane foam. They are an industry standard due to their excellent absorption of liquid and cleaning agents and because of their possibility of designing and combining with other materials (abrasive materials or textile)

Flexible polyurethane foam is used extensively by the clothing and shoe industry. Around 7% od the whole flexible polyurethane market is used for footwear and almost all shoes today contain polyurethane foam: city shoes, sport shoes, hiking boots, house shoes. Since it’s generally lightweight, comfortable, flexible, has a good abrasion resistance and great long-term mechanical properties, polyurethane is used for producing insoles, midsoles or outsoles.

The main consumer application in the clothing industry is for intimate apparel. 70 to 80% of all bras are made with polyurethane foam cups. Foam is also used for shoulder pads and protective clothing.

Many indoor and outdoor sport floors have a polyurethane-based shock pad underlay. Polyurethane foam is also used in many other protective sport applications, such as for example protective equipment for contact sports or crash barriers for motor sports. In small quantities, PU foam can be found in football and swimsuits.

As in homes and offices, polyurethane foam helps absorbing noise in sport halls but also in many other places of leisure such as theatres and cinemas… where you can enjoy plays and movies at ease in seats filled with foam.

Polyurethane foam is used in special pressure-reducing mattresses in hospitals. It is also present in wheelchair cushions, positioning cushions and used in collars, prostheses or advanced wound-care products such as medical dressings and bandages.

Polyurethane foam is used in many cosmetic applications, such as eye shadow applicators, foot sponges, facial sponges and cosmetic powder puffs.

It is expected that the market share of polyurethanes compared to other plastics in cosmetics industry will grow significantly, in view of the increasingly demanding requirements, such as elastic properties, shape memory effects, surface feel, gloss, water resistance, reduction of organic solvent content etc.

Polyurethane foam is present in many products where we might not expect it, from the filters of our vacuum cleaners to those of our aquarium or even in the battery of our cell phones. Some more expected PU applications include cover for phones, wipers, soft freezing bags, soft toys, polishing pads, diapers… its applications and the benefits it provides are countless.

Foam paint rollers & paint pads

Foam paint rollers are among the most popular paint application tools worldwide. They are easy to clean and can be re-used many times. They reduce the spillage of paint as well as the amount of paint needed to do the job.

Next to paint rollers, paint pads can also be made out of polyurethane foam. They drip less than classic paint brushes and – similar to rollers – they require less paint for the same surface. Paint pads can come in many different shapes, to allow precise painting in corners, close to doors or around electrical outlet sockets.

Agriculture

Flexible polyurethane foam is increasingly using in agriculture. Notably, it is used in greenhouses as a substrate for hydroponic production of vegetables, for example cucumbers or tomatoes. In this application, the foam serves to hold water and nutrients for the plant, while offering a maximum air/water ratio throughout its lifetime. This results in higher yields.

Urban design

Due to its properties, there are continuous innovations in PU applications. Examples include vertical wall gardens and green roof systems. In the later, polyurethane foam serves as water storage mats. It has an immediate positive effect on rainwater management and air temperature in immediate vicinity.

Polyurethane foam is used widely by manufacturing industries for acoustic insulation, packaging, noise reduction, vibration and shock absorption, water and air sealing or filtration. Herewith just a few examples:

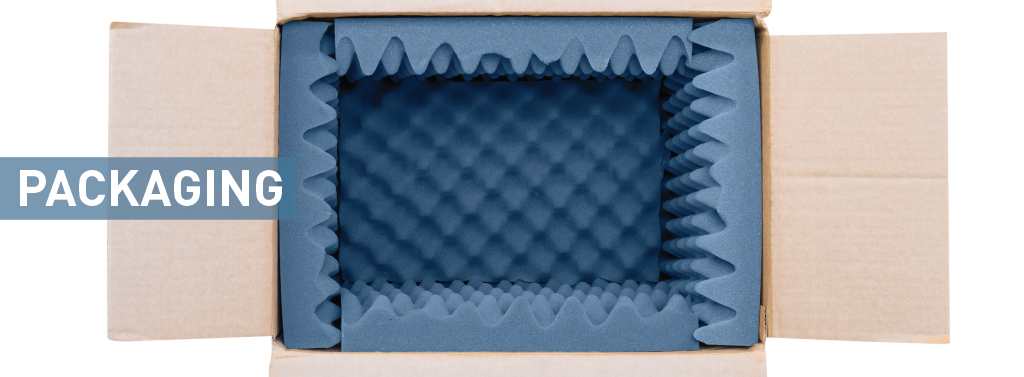

Foam packaging material has excellent shock absorption properties. Moreover, the shape of the foam packing material can be entirely customised to precisely fit the item to be transported. That helps ensuring that fragile items can reach consumers undamaged.

Polyurethane foam packaging is mainly used for wrapping electrical appliances, glass and ceramic products and for furniture of a higher price range.

It is widely understood that polyurethane foam can be used as an air, water or other fluid filter in industrial applications. This is possible thank to its cell structure, which can be adapted precisely to fit requirements.

But few know that polyurethane foam is also essential for metal foundry filters. How can foam help filtering hot liquid metals? The foam serves as a “mould” in which ceramics are injected under pressure. Once solid, the combination of foam and ceramics is heated for the foam to burn. This process leaves a perfectly working ceramic filter with a cell structure for metal foundries. The same process is used to produce the “Nickel foams”, used in batteries.

Our modern environment generates a lot of noise and we all aspire to some peace and quietness from time to time. That’s where flexible polyurethane foams jump in to help.

They are used as acoustic insulation in floors, ceilings or walls within houses, but also in any other building where sound absorption is required to increase comfort (for example schools, offices, call centres, restaurants, theatres, recording studios, factories, or swimming pools) filled with foam.